What is the recommended flow rate for a typical stainless steel filter?

The recommended flow rate for a typical stainless steel filter varies widely depending on factors like filter type, size, design, filtration precision, and fluid properties (e.g., viscosity, temperature). There is no one-size-fits-all "standard" flow rate, but the guidelines below can help you estimate appropriate ranges for common applications.

1. Flow Rate Ranges by Filter Type

Different filter designs have inherent flow rate capabilities based on their structure and media surface area.

A. Basket Filters (Coarse Filtration)

- Design: Simple cylindrical baskets with mesh or perforated plates (e.g., 20–200 mesh).

- Common Sizes:

- Small: 1–4 inch nominal pipe size (NPS), handles 1–10 GPM (227–2,270 L/h).

- Medium/Large: 6–12 inch NPS, handles 50–500 GPM (11,355–113,550 L/h).

- Applications: Pre-filtration in water systems, oil pipelines, or industrial processes with high particulate loads.

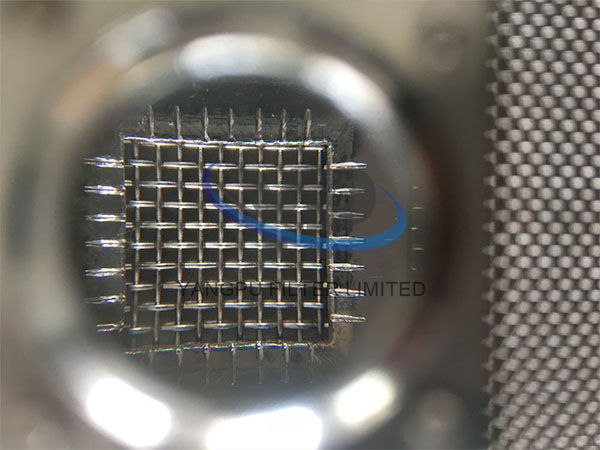

B. Cartridge Filters (Fine to Ultra-Fine Filtration)

- Design: Cylindrical cartridges with pleated, melt-blown, or sintered media (e.g., 0.1–100 microns).

- Common Sizes:

- 10-inch cartridge: Handles 1–5 GPM (227–1,135 L/h) for low-viscosity fluids (e.g., water).

- 20-inch cartridge: Handles 5–10 GPM (1,135–2,270 L/h).

- 40-inch cartridge: Handles 10–20 GPM (2,270–4,540 L/h).

- Multi-Cartridge Housing: Systems with 7–49 cartridges can handle 100–1,000+ GPM (22,700–227,000+ L/h).

- Key Note: Flow rate decreases with finer micron ratings (e.g., a 0.2-micron cartridge may handle half the flow of a 5-micron cartridge of the same size).

C. Disc Filters (High-Flow, Low-Pressure Drop)

- Design: Stacked discs with channels for fluid flow, ideal for high-volume, moderate-precision applications (e.g., 20–200 microns).

- Flow Rate:

- Single disc: 20–100 GPM (4,540–22,700 L/h).

- Multi-disc systems: 500–5,000+ GPM (113,550–1,135,500+ L/h).

- Applications: Irrigation, wastewater treatment, and industrial cooling systems.

D. Membrane Filters (Ultra-Fine Filtration)

- Design: Thin-film membranes for precision separation (e.g., reverse osmosis, 0.0001–0.1 microns).

- Flow Rate:

- Small modules: 0.1–1 GPM (22.7–227 L/h).

- Industrial modules: 10–100 GPM (2,270–22,700 L/h).

- Constraint: Flow rate is highly dependent on pressure (e.g., RO systems require 100–800 psi) and membrane surface area.

2. Factors Influencing Flow Rate Recommendations

A. Fluid Viscosity

- Low-Viscosity Fluids (e.g., water, solvents):

- Higher flow rates are possible (e.g., a 10-inch cartridge can handle 5 GPM for water).

- High-Viscosity Fluids (e.g., motor oil, honey):

- Flow rates drop significantly. For example, the same 10-inch cartridge may handle only 1–2 GPM for oil (viscosity ~100 cP).

- Rule of Thumb: For every 10x increase in viscosity, flow rate decreases by ~50% (assuming constant pressure).

B. Filtration Precision (Micron Rating)

- Coarse Filtration (50–200 microns):

- Higher flow rates (e.g., basket filters at 50 GPM).

- Fine Filtration (1–50 microns):

- Lower flow rates due to tighter media (e.g., cartridge filters at 5 GPM).

- Ultra-Fine Filtration (<1 micron):

- Significantly reduced flow rates (e.g., membrane filters at 1 GPM).

C. Pressure and Pressure Drop

- High-Pressure Systems (e.g., hydraulics, 100–300 bar):

- Smaller filters can handle higher flow rates due to forced fluid movement.

- Low-Pressure Systems (e.g., gravity-fed systems):

- Flow rate is limited by inlet pressure, requiring larger filters to maintain throughput.

D. Filter Geometry and Media Surface Area

- Pleated Filters: Higher surface area allows higher flow rates than non-pleated designs (e.g., a pleated 40-inch cartridge may handle 20 GPM vs. 10 GPM for a standard cartridge).

- Multi-Element Housings: Using multiple cartridges in parallel increases total flow rate (e.g., 10 cartridges × 10 GPM each = 100 GPM).

3. Industry Standards and Manufacturer Guidelines

Most filter manufacturers provide flow rate vs. pressure drop curves for their products. Here are examples from common industries:

A. Water Treatment

- Typical Flow Rates:

- Residential RO systems: 0.5–2 GPM (113–454 L/h) (0.0001–0.1 micron).

- Industrial water filters (20 microns): 50–200 GPM (11,355–45,420 L/h) for 40-inch pleated cartridges.

- Example Chart:

| Filter Size | Micron Rating | Flow Rate (GPM) | Pressure Drop (psi) |

|---|

| 10-inch cartridge | 5 | 3–5 | <1 at 5 GPM |

| 40-inch cartridge | 5 | 10–15 | <1 at 15 GPM |

B. Oil and Lubrication Systems

- Typical Flow Rates:

- Hydraulic filters (10–20 microns): 10–50 GPM (2,270–11,355 L/h) for medium-sized systems.

- Turbine oil filters (1–5 microns): 50–200 GPM (11,355–45,420 L/h) in multi-cartridge housings.

- Key Consideration: Oil filters often require high dirt-holding capacity, so flow rates may be limited by media thickness rather than pressure.

C. Food and Beverage Industry

- Typical Flow Rates:

- Beverage filtration (0.5–5 microns): 5–20 GPM (1,135–4,540 L/h) for sanitary cartridge filters.

- Syrup or sauce filtration (20–50 microns): 10–30 GPM (2,270–6,810 L/h) using basket or disc filters.

4. How to Determine the Right Flow Rate for Your System

- Calculate Required Flow Rate:

- Based on process demand (e.g., "I need to filter 10,000 L/h of water").

- Account for Viscosity and Precision:

- Adjust flow rate downward for viscous fluids or fine filtration.

- Apply a Safety Factor:

- Use a 1.5–2x safety factor to avoid exceeding the filter’s capacity as it accumulates contaminants (e.g., if nominal flow is 10 GPM, choose a filter rated for 15–20 GPM).

- Consult Manufacturer Data:

- Use their flow rate charts or request custom sizing for unique applications.

Example: Selecting a Filter for a Beverage Line

- Requirements: Filter 5,000 L/h (1,320 GPM) of apple juice (viscosity ~2 cP) to 5 microns.

- Steps:

- Convert L/h to GPM: 5,000 L/h ≈ 1,320 GPM (1 L/h = 0.264 GPM).

- Choose a pleated cartridge filter (high surface area for 5 microns).

- Manufacturer data: A 40-inch pleated cartridge handles 15 GPM at 5 microns.

- Calculate required cartridges: 1,320 GPM / 15 GPM per cartridge = 88 cartridges.

- Use a multi-cartridge housing with 90 cartridges (safety factor of 1.02).

Key Takeaways

- No Universal Flow Rate: Always reference the filter type, size, and manufacturer specifications.

- Prioritize Pressure Drop: Ensure the flow rate does not cause excessive ΔP (typically <2 bar for most systems).

- Test and Adjust: For critical applications, validate flow rate with pilot testing to account for real-world conditions (e.g., temperature, contaminant variability).

By aligning your system’s needs with these guidelines, you can select a stainless steel filter that balances performance, efficiency, and cost.