What are the different types of stainless steel mesh and their specific applications?

Stainless steel mesh is categorized into different types based on weave patterns, wire diameter, mesh count (wires per inch), and alloy composition. Each type is designed for specific applications, balancing factors like filtration precision, durability, flow rate, and cost. Below is a detailed breakdown of common types and their uses:

1. Plain Weave Stainless Steel Mesh

Weave Structure:

- Simple crisscross pattern where each warp wire crosses over and under each weft wire.

- Balances cost, durability, and filtration efficiency.

Key Characteristics:

- Moderate strength and flexibility.

- Widely available in mesh counts from 10 to 500 mesh (coarse to medium-fine filtration).

- Particle retention: ~150 microns (100 mesh) to ~30 microns (500 mesh), depending on wire diameter.

Applications:

- General Filtration: Water treatment strainers, air filters, and oil/gas pipeline filters.

- Food Industry: Sieving flour, sugar, or grains; brewery mash filters.

- Agriculture: Grain sorting, livestock fencing, and insect screens (e.g., window screens).

- DIY Projects: Garden fencing, craft projects, and decorative screens.

Example: A 100-mesh plain weave mesh is used in water filters to remove sediment like sand and rust particles.

2. Twill Weave Stainless Steel Mesh

Weave Structure:

- Wires interlace over two or more wires, creating a denser, more stable pattern than plain weave.

- Reduces wire movement, making it more durable for heavy-duty use.

Key Characteristics:

- Higher tensile strength than plain weave.

- Mesh counts typically range from 20 to 400 mesh.

- Smoother surface compared to plain weave, reducing particle trapping.

Applications:

- Industrial Sieving: Mining (sorting ores and aggregates), powder processing (e.g., ceramics, cosmetics).

- Chemical Filtration: Filtering slurries or viscous liquids in reactors.

- Abrasive Environments: Sandblasting cabinets (resists wear from particles).

- Heavy-Duty Screens: Rock crushers and vibrating screens in construction.

Example: A 50-mesh twill weave is used in mining to separate coarse gravel from sand.

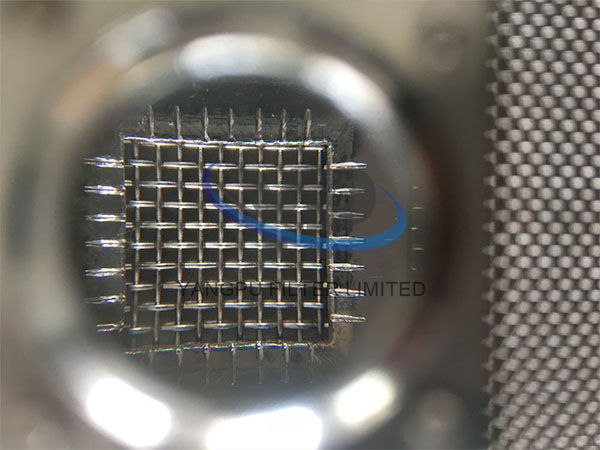

3. Dutch Weave Stainless Steel Mesh

Weave Structure:

- Combines thick warp wires (vertical) and thin weft wires (horizontal) for high precision.

- Two subtypes:

- Standard Dutch Weave: Fine weft wires for ultra-fine filtration.

- Reverse Dutch Weave: Thick weft wires and thin warp wires for high flow rates with fine particle retention.

Key Characteristics:

- Extremely precise particle retention (down to 1 micron in specialized weaves).

- Mesh counts: 200 to 3000 mesh (standard Dutch) or lower mesh counts with fine weft wires (reverse Dutch).

- High structural integrity despite fine weft wires.

Applications:

- Ultra-Fine Filtration:

- Pharmaceuticals (filtering liquids for contaminants).

- Electronics (cleanroom air filters, semiconductor manufacturing).

- Beverages (clarifying wine, beer, or fruit juices).

- High-Flow Applications (Reverse Dutch):

- Oil refineries (filtering lubricants or fuels).

- Water desalination (pre-filtration stages).

- Chemical reactors (catalyst support with balanced flow and particle retention).

Example: A 1000-mesh standard Dutch weave is used in pharmaceutical labs to filter bacteria from liquids.

4. Precious Metal Weave (Specialized Dutch Weave)

Weave Structure:

- A variant of Dutch weave using platinum or palladium-coated stainless steel wires for extreme chemical resistance.

Key Characteristics:

- Resists corrosion from strong acids (e.g., sulfuric acid, nitric acid).

- Maintains filtration precision in high-temperature or high-chemical environments.

Applications:

- Chemical and Petrochemical Industries: Filtering aggressive solvents or acids.

- High-Purity Labs: Handling sensitive chemical reactions in research.

Example: Used in battery manufacturing to filter electrolytes without metal contamination.

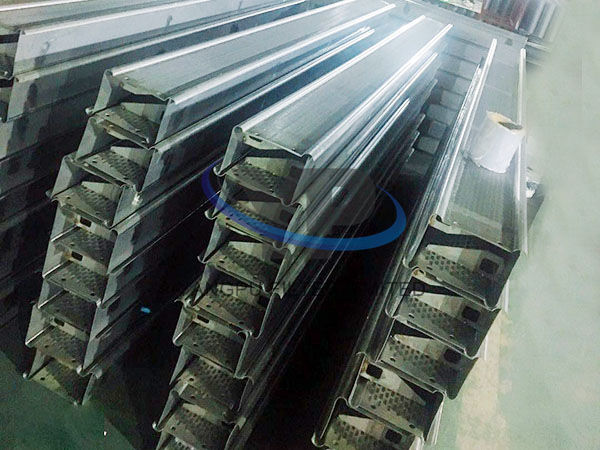

5. Crimped Wire Mesh (Heavy-Duty Weave)

Weave Structure:

- Wires are crimped (bent) before weaving, creating a rigid, open structure with high tensile strength.

Key Characteristics:

- Large openings (low mesh count, e.g., 2 to 20 mesh).

- Extremely durable and resistant to impact.

Applications:

- Mining and Aggregate Processing: Separating large rocks and ores on conveyor belts.

- Industrial Screening: Coal processing, gravel sorting, and waste recycling.

- Animal Caging: Heavy-duty enclosures for livestock or wildlife.

Example: A 5-mesh crimped mesh is used in quarrying to separate boulders from gravel.

6. Micro-Porous Stainless Steel Mesh (Sintered or Welded)

Structure:

- Made by sintering (fusing) ultra-fine stainless steel fibers or wires into a porous matrix.

- Alternatively, welded at intersection points for rigidity.

Key Characteristics:

- Uniform pore sizes (1 to 100 microns).

- High structural integrity and resistance to high pressure.

Applications:

- Medical Devices: Implantable filters (e.g., vascular filters to trap blood clots).

- Aerospace: Fuel filters and hydraulic system filters.

- Semiconductor Industry: Ultra-clean fluid filtration in chip manufacturing.

Example: Sintered mesh with 5-micron pores is used in aircraft fuel systems to prevent debris from damaging engines.

7. Architectural Stainless Steel Mesh

Weave Structure:

- Decorative weaves with open patterns, often in larger mesh counts or artistic designs.

- Made from 304 or 316 stainless steel for aesthetics and corrosion resistance.

Key Characteristics:

- Lightweight, flexible, and visually striking.

- Available in plain, twill, or custom weaves for design versatility.

Applications:

- Interior Design: Room dividers, staircase balustrades, and ceiling panels.

- Exterior Facades: Solar shading screens, building envelopes, and decorative cladding.

- Retail and Exhibitions: Display panels and signage.

Example: A large-opening twill weave mesh is used as a modern architectural screen for a commercial building, providing shade while maintaining visibility.

8. Filter Cartridge Mesh (Composite Structures)

Structure:

- Layered mesh (e.g., combination of plain and Dutch weave) or mesh wrapped around a core (e.g., perforated metal) for support.

Key Characteristics:

- Multi-layered for enhanced filtration (coarse pre-filter + fine final filter).

- Customizable for specific flow rates and particle sizes.

Applications:

- Industrial Filtration Systems: Hydraulic oil filters, paint filtration, and wastewater treatment.

- Food and Beverage: Sterile filtration of liquids (e.g., dairy, pharmaceuticals).

Example: A filter cartridge with a 20-mesh plain weave outer layer (coarse filtration) and a 500-mesh Dutch weave inner layer (fine filtration) is used in a brewery to clarify beer.

Choosing the Right Type: Key Considerations

- Filtration Precision:

- Use Dutch weave for sub-micron particles; plain or twill weave for coarser filtration.

- Environment:

- 316 stainless steel for marine, chemical, or saltwater environments; 304 for general use.

- Mechanical Stress:

- Crimped or twill weave for high-impact applications; sintered mesh for high-pressure systems.

- Aesthetics vs. Functionality:

- Architectural mesh for design-focused projects; filter cartridge mesh for industrial efficiency.

By matching the weave type, alloy, and mesh count to your application’s needs, stainless steel mesh can deliver optimal performance in durability, filtration, and functionality.