Stainless steel mesh

Stainless steel mesh is a versatile material made by weaving stainless steel wires into a grid-like structure. It is valued for its corrosion resistance, durability, strength, and precise filtration properties, making it widely used in industrial, commercial, and residential applications. Below is a detailed overview of its characteristics, types, applications, and key considerations.

Key Characteristics of Stainless Steel Mesh

Material Composition

- Primarily made from stainless steel alloys (e.g., 304, 316, 316L), which contain chromium (for corrosion resistance) and nickel (for durability and strength).

- 304 stainless steel: Commonly used for general applications (non-marine, non-chemical environments).

- 316/316L stainless steel: Offer superior corrosion resistance (ideal for marine, pharmaceutical, and chemical applications due to molybdenum content).

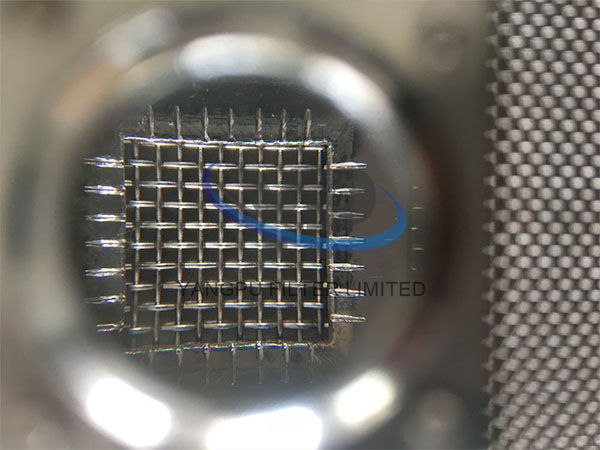

Weave Types

- Plain Weave: The simplest and most common weave, with wires interlaced in a crisscross pattern (e.g., 10 mesh to 500 mesh).

- Twill Weave: Wires interlace over two or more wires, creating a denser, more durable structure (used for medium to fine filtration).

- Dutch Weave: Combines thick warp wires and thin weft wires for high precision (e.g., 200 mesh to 3000 mesh, used in ultra-fine filtration).

- Reverse Dutch Weave: Thick weft wires and thin warp wires, ideal for high-flow applications with fine particle retention.

Mesh Count and Micron Rating

- Mesh count: The number of wires per linear inch (e.g., 20 mesh = 20 wires/inch). Higher mesh count = smaller openings = finer filtration.

- Micron rating: The approximate maximum particle size that can pass through the mesh (e.g., 100 mesh ≈ 150 microns; 300 mesh ≈ 50 microns).

- Note: Actual micron rating depends on wire diameter and weave tightness.

Common Applications of Stainless Steel Mesh

1. Filtration and Separation

- Industrial Filtration:

- Water treatment (sediment filters, strainers).

- Oil and gas (separating solids from fluids in pipelines).

- Chemical and pharmaceutical industries (filtration of liquids, powders, and gases).

- Air Filtration: HVAC systems, dust collectors, and air purifiers.

- Food and Beverage: Brewing (mash filters), wine clarification, and sieving of powders (e.g., flour, sugar).

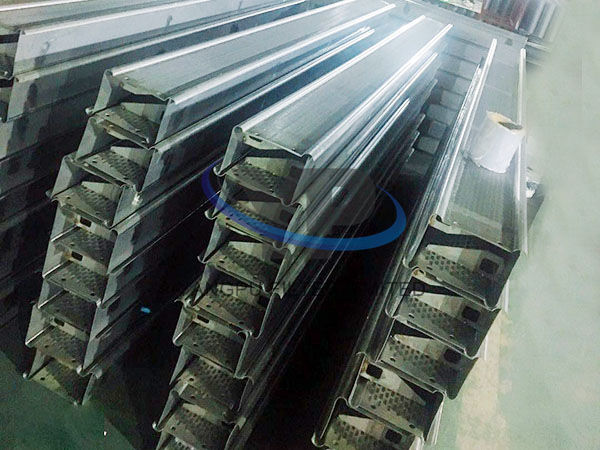

2. Screens and Sieves

- Mining and aggregate processing (sorting rocks, sand, and minerals).

- Powder processing (sieving in cosmetics, pharmaceuticals, and ceramics).

- Recycling (separating materials by size in waste management).

3. Architectural and Decorative Uses

- Balustrades, room dividers, and decorative panels (modern, industrial design).

- Insect screens (windows, doors) due to durability and rust resistance.

- Ventilation grilles (e.g., in kitchens, workshops).

4. Industrial and Mechanical Applications

- Catalyst supports in chemical reactors.

- Heat exchanger screens (distributing fluids evenly).

- Protection screens for machinery (guarding against debris or moving parts).

5. Marine and Outdoor Use

- Boat hull screens (preventing marine growth in cooling systems).

- Coastal erosion control (geotextile-like applications).

- Outdoor furniture and fencing (weather-resistant).

Advantages of Stainless Steel Mesh

- Corrosion Resistance: Withstands exposure to water, chemicals, and harsh environments (critical for marine, pharmaceutical, and food-grade applications).

- High Strength: Resists deformation under pressure, heat, or mechanical stress.

- Precision Filtration: Tight weave options enable consistent particle retention (down to sub-micron levels in specialized weaves).

- Reusability: Can be cleaned and reused (e.g., in industrial filters), reducing waste compared to disposable filters.

- Thermal Stability: Performs well in high-temperature applications (e.g., oven filters, exhaust systems).

Disadvantages and Limitations

- Cost: More expensive than alternative materials (e.g., aluminum or plastic mesh), especially for high-grade alloys (e.g., 316L).

- Clogging Risk: Fine mesh (e.g., >200 mesh) may clog with sticky or fibrous particles, requiring frequent cleaning.

- Weight: Heavier than non-metallic meshes, which may affect portability in some applications.

- Brittleness in Extreme Conditions: Very fine wires in ultra-fine meshes can be fragile if mishandled.

How to Choose Stainless Steel Mesh

Alloy Selection

- 304: General-purpose, non-corrosive environments.

- 316/316L: Marine, chemical, or high-corrosion environments.

- 321/347: High-temperature applications (e.g., furnace filters).

Mesh Count and Micron Rating

- Match the mesh to the particle size you need to retain (e.g., 50 mesh for coarse filtration, 300 mesh for fine powders).

- Use a particle size chart or consult the manufacturer for precise ratings.

Weave Type

- Plain weave: Balances cost and filtration efficiency.

- Dutch weave: Prioritize precision and high particle retention.

- Twill weave: Durability for heavy-duty applications.

Application Requirements

- Flow rate needs (larger openings = higher flow).

- Pressure and temperature conditions.

- Cleanability (smooth surfaces for easy rinsing in food/medical applications).

Custom Fabrication

- Many suppliers offer custom-cut mesh, formed into shapes (e.g., cylinders, cones) or welded into frames for specific uses (e.g., filter cartridges).

Maintenance and Care

- Cleaning: Use non-abrasive brushes, water, or mild detergents. For stubborn deposits, ultrasonic cleaning or chemical solvents (compatible with stainless steel) may be used.

- Inspection: Regularly check for wear, tears, or clogging, especially in high-stress applications.

- Storage: Keep dry to prevent surface rust in low-grade alloys (though 304/316 are highly resistant).

Industry Standards and Regulations

- Food and Pharmaceutical: Mesh must comply with standards like FDA (U.S.) or EC 1935/2004 (EU) for contact with food or drugs.

- Marine: ASTM A240 for stainless steel plate/sheet (used in marine-grade mesh).

- Filtration Efficiency: Tested using standards like ISO 4572 (multi-pass filtration test for hydraulic fluids).

Summary

Stainless steel mesh is a durable, versatile material ideal for applications requiring corrosion resistance, precision filtration, and strength. Its performance can be tailored via alloy choice, weave type, and mesh count, making it suitable for everything from industrial filtration to architectural design. When selecting mesh, prioritize your application’s environmental demands, particle size requirements, and long-term maintenance needs.