Stainless steel filter application

Stainless steel filters are widely used in various industries due to their excellent corrosion resistance, high temperature resistance, durability, and good filtration performance. Here are some of their main application scenarios:

1. Water Treatment Industry

- Municipal Water Supply and Drainage:

- Used in water intake systems to filter out large particles (e.g., debris, aquatic plants).

- Applied in sewage treatment processes for solid-liquid separation (e.g., removing suspended solids in secondary sedimentation tanks).

- Industrial Water Treatment:

- Filters for cooling water systems in power plants and chemical plants to prevent pipeline blockages caused by impurities.

- Ultrafiltration and microfiltration membranes in RO (reverse osmosis) systems, often with stainless steel casings or support structures.

2. Food and Beverage Industry

- Brewing and Beverage Production:

- Filtration of beer, wine, and soft drinks to remove sediments and microorganisms (e.g., stainless steel mesh filters or cartridge filters).

- Food Processing:

- Filtration of edible oils, syrups, and sauces to ensure product purity.

- Sterilization-grade filters in high-temperature environments (e.g., canning and pasteurization lines).

3. Pharmaceutical Industry

- Drug Manufacturing:

- Used in the filtration of raw materials, intermediate products, and finished pharmaceuticals to meet GMP standards (e.g., stainless steel membrane filters for sterile filtration).

- Water for Injection (WFI) Systems:

- High-purity stainless steel filters to remove particulate matter and microbial contaminants in pharmaceutical-grade water systems.

4. Chemical and Petrochemical Industry

- Process Filtration:

- Filtration of chemical raw materials, solvents, and reaction products to remove impurities and catalysts.

- Applications in oil refining (e.g., filtering petroleum fractions, removing mechanical impurities in lubricating oils).

- Corrosive Environments:

- Stainless steel (e.g., 316L) is preferred for filtering aggressive chemicals (e.g., acids, alkalis, and salt solutions).

5. Automotive and Mechanical Engineering

- Lubrication Systems:

- Oil filters in engines and hydraulic systems to trap metal shavings and contaminants, extending component life.

- Air Filtration:

- Stainless steel mesh filters for air intake systems in heavy machinery or high-dust environments.

- Cooling Systems:

- Filters for engine cooling water or industrial coolant loops to prevent scaling and blockages.

6. Aerospace and Marine Industry

- Aerospace Applications:

- High-precision stainless steel filters in aircraft fuel systems, hydraulic systems, and air conditioning systems to ensure reliability under extreme conditions.

- Marine Engineering:

- Seawater filtration systems for desalination plants, ship cooling systems, and ballast water treatment to resist salt corrosion.

7. Metalworking and Mining

- Metal Processing:

- Filtration of cutting fluids, grinding oils, and electroplating solutions to recycle liquids and reduce waste.

- Mining and Mineral Processing:

- Separating valuable minerals from slurries or filtering wastewater to meet environmental discharge standards.

8. Environmental Protection and Air Filtration

- Air Pollution Control:

- Stainless steel bag filters or cartridge filters in industrial dust collectors (e.g., for capturing metal dust, coal dust, or chemical powders).

- Exhaust Gas Treatment:

- Filters in automotive exhaust systems (e.g., diesel particulate filters, DPFs) for emissions reduction.

9. Energy Industry

- Power Generation:

- Filtration in thermal power plant steam systems, nuclear power plant coolant systems, and renewable energy (e.g., biomass fuel filtration).

- Solar and Wind Energy:

- Filters for cleaning cooling fluids in solar thermal systems or lubricants in wind turbine gearboxes.

10. Other Applications

- Aquaculture:

- Water filtration systems in fish farms to remove waste and maintain water quality.

- Paint and Coatings:

- Filtration of paints, inks, and resins to ensure uniform particle size and product quality.

- Laboratory and Research:

- High-precision stainless steel filters for analytical instruments (e.g., HPLC, GC) or experimental sample preparation.

Advantages of Stainless Steel Filters

- Corrosion Resistance: Suitable for harsh environments (e.g., saltwater, chemicals).

- High Temperature Resistance: Can operate in high-temperature pipelines or furnaces.

- Reusability: Easy to clean and maintain, reducing replacement costs.

- Strength and Durability: Resistant to pressure and mechanical stress, ensuring long service life.

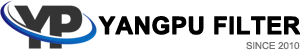

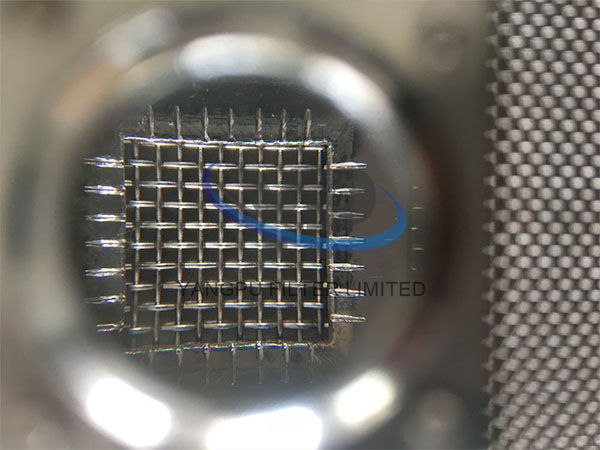

Stainless steel filters are available in various forms, such as mesh filters, cartridge filters, sintered filters, and membrane filters, allowing flexible adaptation to different filtration precision and flow rate requirements across industries.