How to choose the appropriate size of the filter?

Choosing the appropriate size of a stainless steel filter involves considering multiple factors related to the application, fluid properties, and system requirements. Below is a step-by-step guide to help you select the right filter size:

1. Determine Key Operational Parameters

Flow Rate (Q)

- Definition: The volume of fluid passing through the filter per unit time (e.g., m³/h, L/min, GPM).

- How to Measure:

- For existing systems, use flow meters or design specifications.

- For new systems, calculate based on process requirements (e.g., production capacity, pump output).

- Critical Consideration: The filter’s maximum flow rate capacity must exceed the system’s peak flow to avoid pressure drops and bottlenecks.

Pressure and Pressure Drop (ΔP)

- Inlet Pressure: The pressure of the fluid entering the filter (e.g., 10 bar).

- Allowable Pressure Drop: The maximum pressure loss acceptable across the filter (typically 0.5–2 bar for most systems).

- Formula: ΔP = Inlet Pressure – Outlet Pressure.

- Impact: A larger filter size reduces ΔP by providing more filtration area, but excessive size increases costs and space requirements.

Viscosity of the Fluid

- Effect: Higher viscosity fluids (e.g., oils, syrups) require larger filter sizes to maintain flow rate, as they flow more slowly through the media.

- Unit: Measured in centipoise (cP) or Pascal-seconds (Pa·s).

- Tip: Use viscosity charts or consult the filter manufacturer for size recommendations for viscous fluids.

2. Define Filtration Requirements

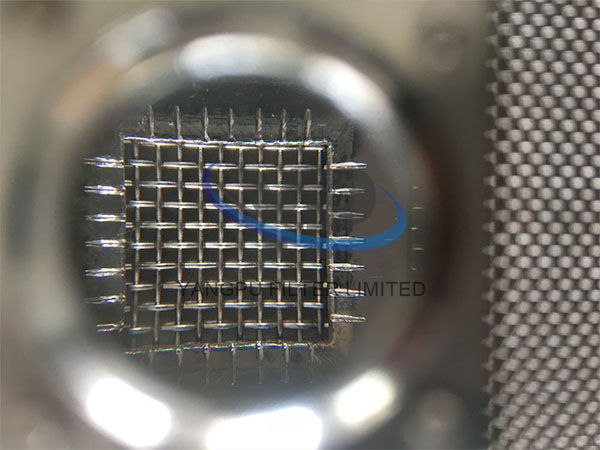

Filtration Precision (Micron Rating)

- Definition: The smallest particle size the filter can remove (e.g., 5 microns, 20 mesh).

- How to Choose:

- Match the micron rating to the application’s purity needs:

- Water treatment: 10–100 microns for coarse filtration; 0.1–5 microns for ultrafiltration.

- Oil systems: 1–20 microns to protect pumps and valves.

- Rule: Smaller micron ratings require more filter media surface area, often necessitating a larger filter size.

Particle Concentration

- Definition: The amount of contaminants in the fluid (e.g., mg/L, PPM).

- Impact: Higher contaminant loads require larger filter sizes or higher dirt-holding capacity (e.g., pleated filters vs. simple mesh filters).

- Key Term: Dirt-Holding Capacity (DHC): The maximum weight of contaminants a filter can retain before clogging. Larger filters have higher DHC.

3. Consider Physical and Environmental Constraints

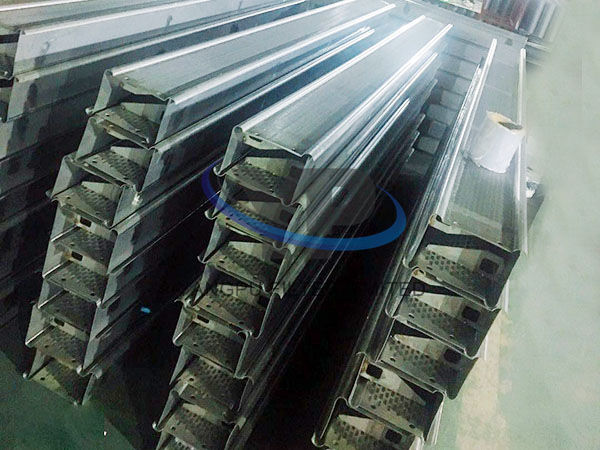

Space and Installation

- Available Space: Ensure the filter fits within the system’s footprint (height, diameter, pipe connections).

- Installation Type:

- In-Line Filters: Require straight pipe sections before/after the filter to maintain flow stability.

- Tank-Mounted Filters: Space constraints may limit filter size.

Temperature and Corrosion

- Temperature: High-temperature fluids (e.g., steam, hot oil) may require heat-resistant stainless steel grades (e.g., 316L, 304) and affect seal materials.

- Corrosion: Aggressive fluids (e.g., acids, seawater) demand corrosion-resistant alloys, but this may not directly impact size unless combined with other factors (e.g., high flow + corrosion = larger stainless steel housing).

4. Select Filter Type and Design

Filter Media and Structure

- Common Types:

- Mesh Filters: Coarse filtration (e.g., 20–500 mesh), suitable for large particles.

- Cartridge Filters: Fine filtration (0.1–100 microns), available in pleated (higher surface area) or string-wound designs.

- Sintered Filters: High-strength, suitable for high-pressure or high-temperature applications.

- Impact on Size: Pleated cartridges or multi-element filters offer larger filtration area in a compact size compared to simple mesh filters.

Flow Pattern

- Direction:

- Radial Flow: Fluid flows from the outside to the inside of a cartridge (common in high-flow systems).

- Axial Flow: Fluid flows through the length of the filter (suitable for low-flow, high-precision applications).

- Tip: Radial flow designs often allow smaller physical sizes for the same flow rate due to higher surface area.

5. Use Manufacturer Guidelines and Calculations

Filter Capacity Charts

- Most manufacturers provide charts linking filter size to flow rate, pressure drop, and micron rating. For example:

- A 10-inch cartridge filter with a 5-micron rating may handle 5 GPM, while a 20-inch cartridge handles 10 GPM.

- Example Calculation:

- Required flow rate = 15 GPM.

- Manufacturer’s data: 10-inch cartridge = 5 GPM, 20-inch = 10 GPM.

- Solution: Use three 10-inch cartridges in parallel or one 40-inch cartridge.

Safety Factor

- Apply a safety factor of 1.5–2.0 to account for:

- Contaminant buildup over time (which increases ΔP).

- Fluctuations in flow rate or viscosity.

- Example: If the nominal flow is 10 m³/h, select a filter rated for 15–20 m³/h.

6. Test and Validate

Pilot Testing

- For critical applications (e.g., pharmaceuticals, aerospace), test a smaller filter prototype to measure:

- Actual pressure drop under operating conditions.

- Filter lifespan before clogging (based on contaminant load).

- Adjustments: If test results show excessive ΔP or short lifespan, increase filter size or switch to a higher DHC design.

System Integration

- Ensure the filter’s connection type (e.g., threaded, flanged, sanitary) matches the pipeline.

- Check for compatibility with accessories (e.g., pressure gauges, bypass valves) to monitor and protect the filter.

Example Scenario: Choosing a Filter for a Water Treatment System

- Parameters:

- Flow rate = 50 m³/h.

- Filtration precision = 20 microns.

- Allowable ΔP = 1 bar.

- Fluid = Municipal water (low viscosity, moderate contaminants).

- Steps:

- Refer to a manufacturer’s catalog for in-line stainless steel basket filters.

- Find a filter with a 20-micron mesh and a flow capacity of ≥75 m³/h (safety factor of 1.5).

- Select a filter with a diameter of 300 mm and length of 600 mm, rated for 80 m³/h and ΔP < 1 bar at full flow.

Key Takeaways

- Prioritize Flow and Pressure: Ensure the filter can handle peak flow without excessive pressure drop.

- Balance Precision and Size: Finer filtration requires more media surface area (larger size or advanced designs like pleated cartridges).

- Consult Experts: Work with filter suppliers to leverage their application-specific data and avoid undersizing/over-sizing.

By systematically evaluating these factors, you can select a filter that optimizes performance, cost, and maintenance for your specific needs.