How is the quality of stainless steel mesh determined?

The quality of stainless steel mesh is determined by several critical factors that affect its performance, durability, and suitability for specific applications. These factors range from material composition to manufacturing precision and compliance with industry standards. Below is a detailed breakdown of how quality is assessed:

1. Material Composition and Alloy Grade

Key Criteria:

- Stainless Steel Alloy: The grade of stainless steel (e.g., 304, 316, 430) directly impacts corrosion resistance, strength, and temperature tolerance.

- 304 (18-8 SS): Standard grade for general use (non-corrosive environments).

- 316 (SS with Mo): Higher corrosion resistance (ideal for marine, chemical, or saltwater applications).

- 430 (Ferritic SS): Magnetic, less corrosion-resistant than austenitic grades (used for screens in dry environments).

- Purity of Raw Materials: Impurities (e.g., sulfur, phosphorus) weaken the mesh and reduce corrosion resistance. High-quality mesh uses low-impurity alloys.

How to Verify:

- Request a mill certificate or material test report (MTR) confirming the alloy composition.

- Use a stainless steel identifier (e.g., a magnet for ferritic vs. austenitic grades) or chemical analysis.

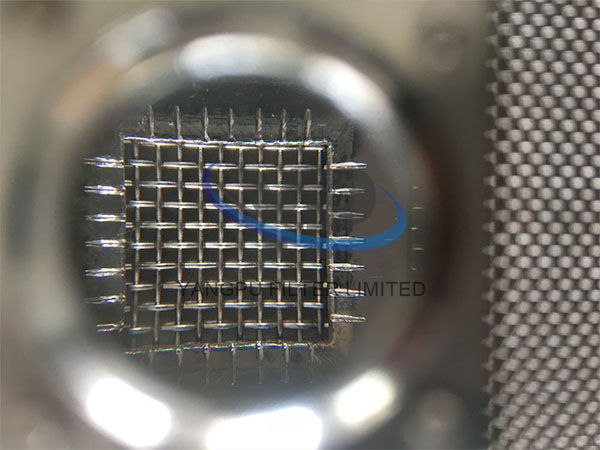

2. Weave Structure and Precision

Key Criteria:

- Weave Type: Ensures the mesh meets the intended use (e.g., plain weave for general filtration, Dutch weave for precision).

- Mesh Count (Wires per Inch): Must match the specified design (e.g., 100 mesh = 100 wires/inch in both directions). Deviations affect particle retention and flow rate.

- Wire Diameter: Thinner wires (e.g., in Dutch weave) enable finer filtration but must maintain structural integrity.

- Open Area Percentage: The ratio of open space to total area; higher open area improves flow rate but reduces particle retention.

How to Measure:

- Use a microscope or mesh counting tool (e.g., a comparator gauge) to check mesh count and wire alignment.

- Calculate open area with the formula:\(\text{Open Area (\%)} = \left(\frac{\text{Mesh Count} \times (\text{Nominal Opening})^2}{1}\right) \times 100\)where Nominal Opening = \(\frac{1}{\text{Mesh Count}} - \text{Wire Diameter}\).

3. Manufacturing Consistency and Defects

Key Criteria:

- Uniformity: Wires must be evenly spaced and tightly woven to avoid gaps or loose wires that compromise filtration.

- Defects:

- Shifts/Offset Wires: Misalignment in the weave (e.g., "dropped" wires in plain weave).

- Nicks or Breaks: Damaged wires reduce strength and create filtration gaps.

- Snags or Burrs: Rough edges can cause particle trapping or damage to adjacent components.

How to Inspect:

- Visually inspect the mesh under bright light for irregularities.

- Use a tension tester to ensure wires are taut and the weave holds structural integrity.

- For critical applications (e.g., pharmaceuticals), perform dye penetrant testing to detect micro-cracks or breaks.

4. Mechanical and Environmental Performance

Key Criteria:

- Tensile Strength: The mesh must withstand operational stress (e.g., pressure in filters or impact in mining screens).

- Corrosion Resistance: Tested via salt spray (ASTM B117) or acid immersion to ensure compliance with industry standards.

- Temperature Tolerance: High-quality mesh retains strength in extreme heat (e.g., 316 SS for applications up to ~870°C).

- Flow Rate and Filtration Efficiency: Matches the specified particle retention (e.g., a 50-micron mesh should trap particles above that size consistently).

How to Test:

- Tensile Testing: Measure the force required to break the mesh (ASTM E8).

- Filtration Testing: Pass a known particle size through the mesh to verify retention rate (e.g., using a beta test for filter efficiency).

- Environmental Testing: Simulate real-world conditions (e.g., humidity, chemical exposure) to assess degradation over time.

5. Compliance with Standards and Certifications

Key Criteria:

- Industry Standards:

- ISO 9001: Quality management system certification for the manufacturer.

- ASTM A240/A240M: Standards for stainless steel plate, sheet, and strip (relevant for mesh materials).

- FDA/USDA Compliance: For food, pharmaceutical, or medical applications (ensures materials are non-toxic and easy to clean).

- NACE MR0175: For mesh used in corrosive oil and gas environments.

- RoHS/REACH Compliance: Ensures no hazardous substances (e.g., lead, cadmium) for environmental and safety standards.

How to Validate:

- Request certification documents (e.g., FDA approval, ISO compliance) from the manufacturer.

- For regulated industries (e.g., medical devices), audit the manufacturer’s quality control processes.

6. Surface Finish and Cleanliness

Key Criteria:

- Smoothness: A polished or electropolished surface reduces particle adhesion and improves cleanability (critical for food or pharmaceutical use).

- Debris-Free: No manufacturing residues (e.g., oil, welding spatter) that could contaminate the application.

How to Ensure:

- Specify surface finish requirements (e.g., Ra ≤ 0.8μm for sanitary applications).

- Use ultrasonic cleaning or particle counting to verify cleanliness.

7. Customization and Tolerances

Key Criteria:

- Dimensional Accuracy: Mesh rolls or sheets must meet specified dimensions (e.g., width, length, thickness) within tight tolerances.

- Custom Weaves: For specialized applications (e.g., architectural mesh), the weave must match the design specifications (e.g., open area, wire pattern).

How to Ensure:

- Use a caliper to measure thickness and wire diameter.

- For custom designs, request a first article inspection (FAI) with detailed dimensional reports.

Summary: Key Quality Indicators for Stainless Steel Mesh

| Factor | Assessment Method | Standards/Tests |

|---|

| Material Composition | Mill certificate, chemical analysis | ASTM A240, ISO 683-16 |

| Weave Precision | Microscope, mesh counting tool | ASTM E2016 (for wire cloth) |

| Mechanical Strength | Tensile testing | ASTM E8 |

| Corrosion Resistance | Salt spray test, acid immersion | ASTM B117, ISO 9227 |

| Filtration Efficiency | Particle retention testing | Beta test (ISO 16889) |

| Compliance | Certification review (FDA, ISO, NACE) | FDA 21 CFR Part 177, NACE MR0175 |

By evaluating these factors, you can determine the quality of stainless steel mesh and ensure it meets the requirements of your application, whether for industrial filtration, food processing, or architectural design. Always source from reputable manufacturers who provide detailed testing and certification documentation.